What is masterbatch?

Masterbatch, commonly known as master or colorant, is a concentrated mixture of pigments or additives dispersed in a carrier resin in the form of pellets.

The main utility of masterbatch lies in its ability to improve efficiency in the production of plastics by allowing the uniform dispersion of additives without the need to handle powders or liquids, which reduces the risk of contamination and facilitates handling. Its use guarantees high repeatability and consistency in coloring, avoiding undesired variations in the final product.

The composition of the masterbatch includes the following main elements:

- Carrier resin: It acts as a vehicle for the additives and pigments, allowing their homogeneous dispersion in the base polymer. It can be composed of polyethylene, polypropylene, polystyrene or other compatible resins

- Pigments or colorants: Responsible for providing the desired coloration to the final plastic.

- Functional additives: May include UV stabilizers, antioxidants, flame retardants, antibacterial agents, among others, to improve the properties of the final product.

- Mineral or reinforcing fillers: Such as calcium carbonate or glass fibers, used to improve the mechanical strength and other characteristics of the plastic.

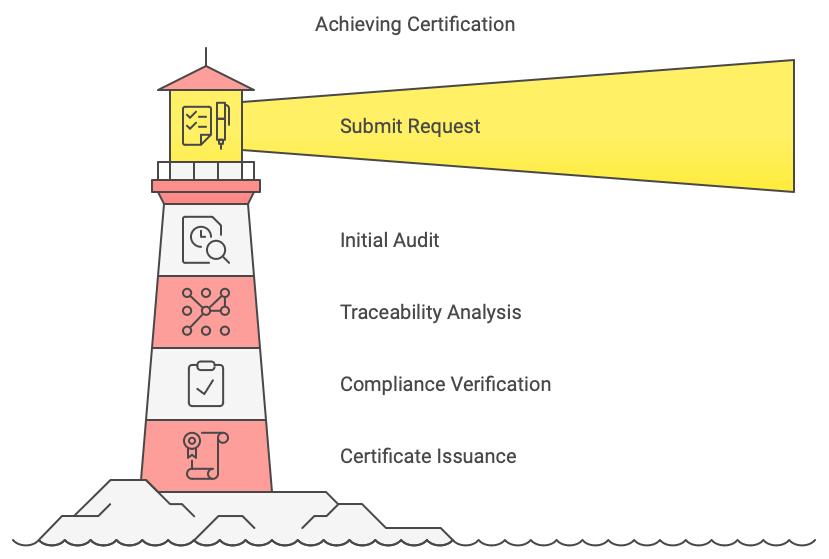

How does the addition of masterbatch affect the recycled % of my production?

Until now, masterbatch has generally been manufactured using virgin material as a carrier resin. This means that the finished product would contain 3 to 5 % non-recycled plastic.

That is, if for the manufacture of a production order of bottles, the production “recipe” has only two raw materials, such as 95 kg of 100% recycled plastic and 5 kg of masterbatch, the percentage of recycled material in the final product would be 95%.

This is a problem that some manufacturers are unaware of and that we find day after day when performing the relevant audits of the UNE-EN 15343 and RETRAY scheme, and is that there is a great ignorance of the fact that this dye affects the final recycled %, reducing the final percentage of recycled plastic, which implies that the final product will not be 100% recycled, as many manufacturers believe, but 95% recycled, which means that the manufacturer must pay a fee for that 5% of non-recycled plastic (calculating for each production order the total kg of non-recycled plastic and multiplying it by the fee of 0.45 €/kg).

If large companies have already trusted EXTERNA, why not you too? Contact us and get certified with the leader in trust and proximity.